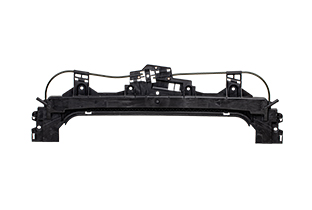

Acot can provide customer with one-stop solution for plastic parts. We are able to manufacture small to medium sized tools up to 200 sets a year.The factory is well equipped with all advanced software for drawings, DFM and mold flow analysis.

With years of experience in plastic tooling, our process control and project management ensures tool projects can meet mass production timeline.We also support customers with quick prototyping at project design phase.

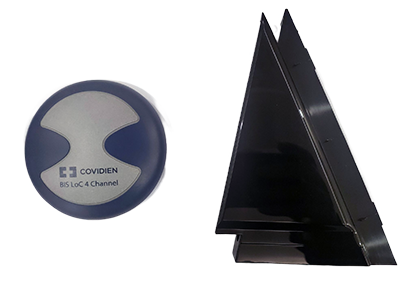

Acot provides a wide variety of plastic parts from general molding to value-added molding.

Electric and hydraulic molding machines ranging from 30 tons to 1000 tons are available in-house to ensure cost-efficient production.

Our thorough process control in mass production, together with the high quality tools, makes Acot the manufacturer of complex plastics parts manufacture.

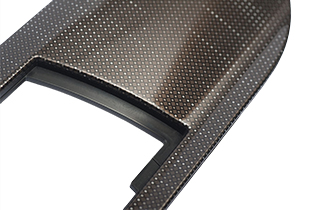

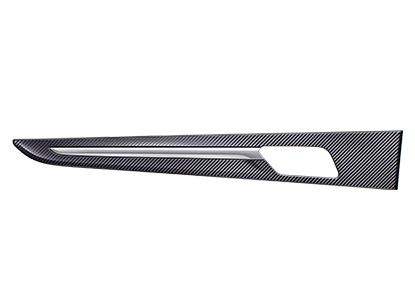

In-Mold Solution is a technique by laminating foil image onto plastic part surface during injection process.

It is widely used in automotive interiors, mobiles devices and home appliances as a decorative or functional layer on top surface.

Acot has been in IMD industry more than 15 years and we gained extensive engineering knowledge and manufacturing experience through all the projects delivered. Various global and local foils are used to meet product specification, and Acot is capable of foil printing in house. Our aim is to provide a one-stop solution meeting the cost & quality targets.

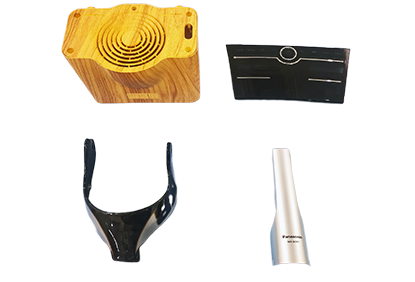

Multiple finishing process are available in-house to achieve customized product design, including spray painting, printing, laser etching, ultrasonic welding. Also we are working constantly to find innovative solutions of surface finishing in the supply chain, and this enables Acot to support our customers with a variety of solutions. This can help customers with shorter development.

Years of manufacturing electronic devices with all kinds of finishing, testing & inspection protocol are well set for new projects and mass production.

Flexible cells and automation lines are designed to meet specific product requirements. Our aim is to provide manufacturing service with optimum productivity and stability.

The engineering team provides innovative solutions on assembly by consolidating functional testing with assembly process to achieve high efficiency and low cost.